SAP EWM Online Training

Description

This SAP EWM Online Training SAP Warehouses EWM S/4 Hana aims to turn the student into a user of the different functionalities of EWM on SAP/4 HANA. You will learn about its organizational structure, master data, main transactions, use of the monitor or radio frequency.

SAP S/4HANA is the new version of the SAP platform that has been implemented as a widespread management tool in medium and large companies, succeeding SAP R/3 and SAP ERP.

You will receive training in SAP S/4HANA Warehouse Management at the expert user level, through a program made up of eminently practical thematic units and with the support of a team of professional teachers in the field.

With exclusive video-class technology, accompanied by online theoretical material, you will be trained in the Warehouse Management (EWM) module, learning step by step everything related to business processes in this area.

You will find detailed definitions and listings of organizational information, master data , and each specific process, along with the corresponding activities and comments .

Today, SAP expert profiles are among the most sought-after and best-paid in the job market. Don’t miss the opportunity to stand out from other candidates by demonstrating your knowledge of SAP S/4HANA, the new generation of SAP’s Business Suite for ERP.

career opportunities

There is currently a high demand for SAP Consultants from large and medium-sized companies. SAP has more than 18 million users, making it the leading supplier of software for the management of large and medium-sized companies.

According to the INE (National Institute of Statistics), more than 40,000 SAP consultants will be hired in the next 4 years. The SAP corporation has developed to become the fifth largest software company in the world.

This training will make you an expert SAP Warehouse Management (EWM) Consultant, which will automatically put you in an advantageous position to work in SAP consultancies or SAP EWM Online Training as an in-house SAP Consultant in companies that use SAP to manage human resources.

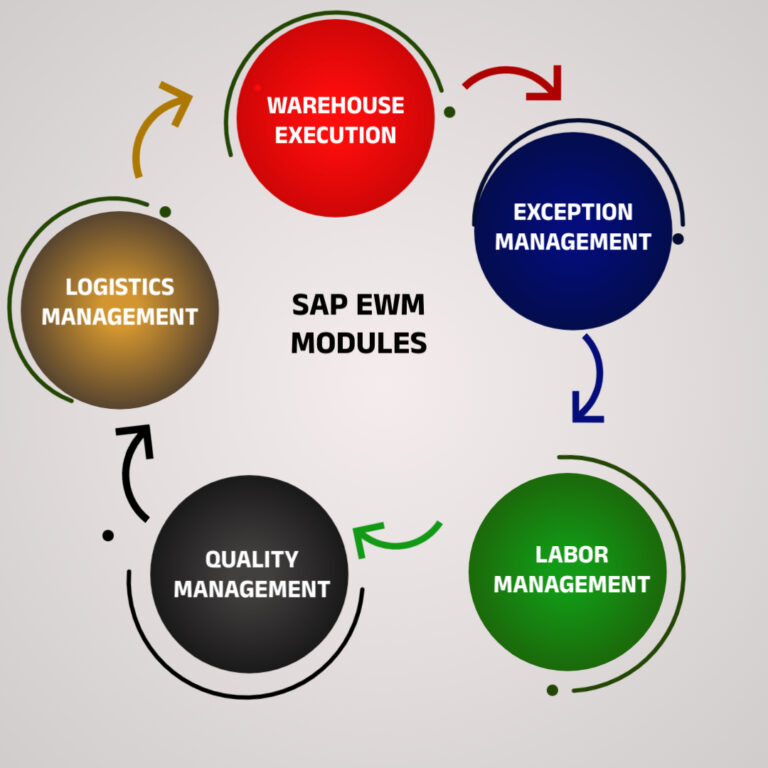

SAP Extended Warehouse Management (EWM) modules have become an integral part of many organizations’ warehousing and distribution operations.

EWM solutions greatly simplify ICT environments and reduce the total cost of logistics management. User engagement and productivity are also improved through a single management solution and a common user experience across all aspects of ERP and warehouse management.

Who is it for?

This EWM online training SAP Warehouses EWM S/4 Hana EWM (Warehouse Management) is aimed at professionals with knowledge in warehouse and/or stock and budget management who wish to enter the SAP world. Also for warehouse managers, administrators and other professionals who, having experience in other management software, wish to justify their knowledge of SAP and, in general, to all those who are interested in developing their professional career in the area of warehouse management of a medium or large company, where SAP has been implemented as a widespread management tool.

SAP Extended Warehouse Management (SAP EWM) module

The SAP Extended Warehouse Management (SAP EWM) module within the SAP ERP system is a comprehensive solution that enhances and extends warehouse management module capabilities beyond those provided by traditional warehouse management ( SAP WM) module. We focus on improving warehouse operations by providing advanced warehouse management, inventory management, order fulfilment and resource optimisation capabilities. This allows companies to increase the transparency, efficiency and accuracy of warehouse processes, and warehouse management ,enabling real-time tracking of Materials movements, efficient picking strategies and optimised resource utilisation. EWM is designed to integrate seamlessly with other SAP modules like SD, FICO and MM to provide a complete solution for end to end supply chain management.

SAP Extended Warehouse Management (SAP EWM) is used to efficiently manage inventory in the Warehouse and for supporting processing of goods movement. It allows the company to control their Warehouse inbound and outbound processes and movement of stocks in the Warehouse.

The main process in a Warehouse is incoming and outgoing materials, goods receipt and goods issue, fulfil customer orders, and distribution of goods and materials. When a company doesn’t store any goods, then there is no need of Warehouse management to manage goods items.

Inbound process involves storage of goods items in warehouse and their location and Outbound process involves picking up the goods. Whenever a material is stored in a warehouse, it is stored in the storage bin and you can find its current location and tack the status also.

With the help of SAP EWM all the goods movements are controlled by warehouse management system and provides you the tools to monitor warehouse activities and tracking. You can also manage additional functions in the Warehouse like creating a serial number, batch number, vendor management inventory, resource optimisation and value added services. SAP Extended Warehouse Management ( SAP EWM ) allows you , not only monitor the quantity of goods in Warehouse but to manage other critical functions and delivery of goods efficiently.

Warehouse Management is opposite to Inventory management. SAP Warehouse management deals with goods movement and monitoring the physical location of the goods recorded with specific documents.

SAP EWM is different from SAP WM (Warehouse Management)

SAP EWM is a part of SAP Supply Chain Management like SAP Warehouse management system but provides more robust and advanced features to manage key activities in the Warehouse.

SAP Extended Warehouse Management is similar to Warehouse management but it provides more advanced features like picking, put away, RF framework, Warehouse structure and more flexible options to manage the warehouse functions.

SAP WM ( Warehouse Management ) add-on is available in SAP ECC , and SAP S4 HANA EWM is available in S4 HANA, From S4 HANA 2020 version onwards Embedded EWM Is available.

You can create new elements like an activity area, resources, labor management and work centers in SAP EWM which were not available in SAP WM.

SAP EWM training provides more best solution to manage warehouse functions in an organisation. It is also a part of SAP Supply Chain Management and also supports all the processes within logistics and supply chain management.

Process EWM module

The processes of the SAP EWM (Extended Warehouse Management) module include three main concepts :

1) Inbound Process

2) Outbound Process

3)Physical Inventory Process

Together, these three processes form the core functionality of SAP EWM, ensuring efficient warehouse management, accurate inventory management and optimised supply chain operations and tracking.

Inbound Process

The Inbound Process in the SAP EWM course (SAP EWM) module refers to all the activities involved in manage the flow of goods items into the warehouse. This includes process of incoming shipments, unloading, performing quality checks and placing orders in designated storage locations and tracking.

The main components of this process :

-

- Goods Receipt: Begins at goods receipt, where the system registers the destination of the product at the warehouse. This stage involves confirming receipt of goods items for incoming deliveries.

-

- Handling and storage: Once goods items have been received, products are often unloaded from incoming vehicles. The SAP EWM system manages the unloading process the place of goods into predetermined storage locations within the warehouse.

-

- Quality control: SAP Extended Warehouse Management handles the quality control processes for incoming products. This involves checking incoming goods with predetermined quality standards. Depending on the results of the inspection, goods may be rejected, accepted or flagged based inspection.

-

- Decomposition: When products are received in consolidated shipments, the receiving process may include decomposition, which involves dividing larger shipments into individual large items or smaller items units for more efficient storage type and handling.

- Handling units: SAP EWM enables the management of handling units, which are goods materials.

-

- Cross docking: SAP Extended Warehouse Management supports cross docking, a strategy in which incoming goods are immediately transfer from the receiving area to the shipping area without need for storage. This strategy used to speed up the fulfilment of customer orders. The incoming process in SAP EWM is tightly integrated with other SAP modules, such as SAP Materials Management and SAP Sales & Distribution , ensuring a seamless and consistent flow of data throughout the ERP process.

Outbound Process

The outbound process in the SAP EWM (Extended Warehouse Management) module refers to all the activities and procedures involved in managing the flow of goods out of the warehouse and tracking. It encompasses the processes of order fulfilment, item picking and packing, and delivery of products to customers. The key components of the outbound process in SAP EWM are as follows :

Outbound order processing : the process begins with the receipt of outbound orders from SAP SD (Sales and Distribution) or other relevant modules. Outbound orders can include sales orders, delivery orders.

Order Confirmation : Once the outbound orders have been received, the SAP EWM system confirms stock availability and confirms the order. This step involves check the inventory to ensure that the requested items are in stock and can be allocated to the outbound order.

Picking : The picking process involves selecting items from their storage location according to the requirements of the outbound order. SAP EWM supports various selection strategies, such as wave selection, cluster selection and zone selection, to optimize the selection process and increase efficiency.

Packaging : The Packaging after collection, items are packaged using appropriate packaging materials. SAP EWM enables the management of packaging materials and supports packaging processes that may include the consolidation or separation of items according to specific business requirements.

Handlers : SAP EWM manages handlers during the shipping process, ensuring that items are correctly grouped and packed for shipment. Handling units can include pallets other containers.

Loading : Once items have been packed next step is the loading process. SAP EWM helps to optimize loading by providing advice on loading sequences and ensuring that the right items are loaded onto the right transport vehicle.

Shipping : Shipping process ends with the goods being transported to the designated location. SAP EWM integrates with carriers and shipping services, creates shipping documents and labels, and tracks the status of shipments.

Physical Inventory Process

The Physical Inventory process in the SAP Extended Warehouse Management (SAP EWM) module involves systematically counting and verifying the actual stock level in the warehouse and matching it with the inventory recorded in the system. This process is essential for maintaining accurate inventory records and identifying discrepancies and ensuring reliable supply chain operations. A key element of the inventory process in SAP EWM is ‘count and control‘.

EWM (Extended Warehouse Management)

SAP EWM course online is applied to efficiently manage inventory in the Warehouse and for supporting the processing of goods movement. It allows the company to control its Warehouse inbound and outbound processes and the movement of goods in the Warehouse and tracking.

The main method in a Warehouse is incoming and outgoing goods materials, goods receipt and goods issue, fulfill customer orders and distribution of goods items. When a company doesn’t store any goods, then there is no need for Warehouse management to manage goods items.

The inbound process includes the storage of goods in the warehouse and their location and the Outbound process includes picking up the goods items. Whenever a material is stored in a warehouse, it is stored in the storage bin and you can find its current location and tracking also.

With the help of SAP EWM (Extended Warehouse Management), all the goods items movement is controlled by a warehouse management system and provides you the tools to monitor warehouse activities. You can also manage additional functions in the Warehouse like creating a serial number, batch number, vendor management inventory, resource optimisation, and value added services. SAP Extended Warehouse Management enables you to monitor the number of goods in the Warehouse but to manage other critical functions and delivery of goods items efficiently.

Key Features of SAP Extended Warehouse Management

The following are the key features of SAP EWM −

-

- Using SAP EWM, you can command the warehouse activities like picking, posting, and managing storage box and good receipts and tracking also.

-

- You can determine storage concepts applying to slot for product items and optimise the arrangement of goods items warehouse automatically.

-

- It allows you to control and track vehicles as well as other transportation units from the terminal check-in to yard check-out, including movements and other tasks within the yard.

-

- EWM also includes storage and handling of hazardous substances and their transportation by the regulations from SAP Environmental Health & Safety EHSM and EHS.

-

- You can perform consolidation of handling units that contain different products before putting them away in different storage locations and sections.

-

- It allows you to perform executable tasks like work packages, existing of warehouse tasks warehouse employees should perform as part of warehouse management activities.

-

- You can set an alert for changed data before goods receipt from SAP EWM to the ERP system, reversal or correction of the receipt of the goods from SAP EWM to the ERP system, and an inbound delivery split from SAP EWM to the ERP system.

-

- In SAP EWM, you can also plan labour time schedule and use resources more effectively, and hence you can make your Warehouse efficient by managing key resource management tasks effectively and monitor the tracking.

-

- You can use cross docking that allows you to perform transportation of handling units across different distribution centres or warehouses till they reach their Destination location in the Warehouse.

SAP EWM Training Course Contents:

➢ Setting Up the EWM Warehouse in S4 HANA EWM

➢ Setting Up Delivery Document Integration

➢ Setting up ERP-EWM integration – sap ewm online training

➢ Availability group set up in S4 EWM.

➢ EWM Differences in S4 and Non S4 system

➢ Creating Structural Elements in SAP EWM S4 HANA

➢ Creating Storage Bins manually and automatically

➢ Bin Sorting - sap ewm online training

➢ Creating Work Centres

➢ Activities and Activity Areas

➢ Creating Warehouse Product Master Data

➢ Staging Area and Door determination

Applying Warehouse Process Types

➢ Automatic determination of WPT - sap ewm online training

➢ WPT set up for Storage Control

➢ Handing Unit types

➢ Handling Unit Group - sap ewm online training

➢ Handling Unit configuration for the warehouse

➢ Outlining Goods Receipt Processes in SAP EWM

➢ Setting Up Availability Groups for Inventory Management (IM)

➢ Configuring Direct Putaway

➢ Applying Putaway Rules - sap ewm online training

➢ Outlining the Goods Issue Process in SAP EWM

➢ Applying the Stock Removal Strategies

➢ Configuration of Packaging Specification

➢ Packaging Specification creation

➢ Condition Records maintenance in Packaging Specification

➢ Packing the Inbound delivery

➢ Performing Posting Changes and Stock Transfers

➢ Performing Ad Hoc Movements and Replenishment

➢ Different types of Replenishment procedures in EWM

Physical Inventory - sap ewm online training

➢ Outlining the Physical Inventory Process

➢ Setting Up the Procedures for Physical Inventory

➢ Outlining the PPF - sap ewm online training

➢ Applying the PPF in Delivery Processing

➢ Label printing

➢ Automatic WT creation through PPF

➢ Picklist/WO/Physical Inventory countsheet printing

➢ Overview of waves - sap ewm online training

➢ Setting up wave templates

➢ Manual and automatic wave creation

➢ Condition records for wave creation

➢ Implementing Two-Step Picking

➢ Outlining Storage Control

➢ Process-Oriented Storage Control for Inbound and Outbound process

➢ Layout-Oriented Storage Control for Inbound and Outbound Process

➢ Deconsolidation and Packing work station - sap ewm online training

➢ Overview of Yard Management

➢ Configuration and Master data setting in Yard Management

➢ Creating the Transportation Units

➢ TU movement within Yard - sap ewm online training

➢ Resource types and resource group

➢ Different types of Queues - sap ewm online training

➢ Queue determination in different processes

➢ RFUI set up for Inbound Process

➢ RFUI set up for outbound process

➢ RFUI set up for Internal Warehouse Process

➢ Configuring Exception Handling - sap ewm online training

➢ EWM driven opportunistic cross docking

➢ Configuration and master data set up